| April 6, 2011 |

|

Working with Weight Scale: Basic Information and Tenets of the Ton(ne)

Matt Fonseca, UNECE/FAO Forestry and Timber Section,

Geveva Switzerland. Matt gave an overview of the drivers of weight to

volume ratios based on his experience in working with weight in western

North America and in the southeast of the US. He also provided some

information on some of the different add-ons and controls used in

conjunction with weight to minimize risk when weight as used as the

transaction unit. Click

here to view the presentation.

|

|

|

Transacting Logs by Weight: A Western US Overview

Neal Hart, Jendro

& Hart LLC, Sunriver, Oregon. Neal provided some background on why

the use of weight and cubic is increasing in the Western US. He also

provided some comparisons of weight and volumes in cubic and

Scribner, noting that the relationship between weight and cubic volume

is quite predictable and linear, while the relationship between weight

and Scribner volume is erratic and not very predictable, especially given

the high percentage of small diameter logs that is now common in the

region. In addition, Neal provided some information on relationship

with value and some of the pitfalls when using conversion factors for weight to Scribner volume. Click here to view the

presentation.

|

|

|

Selling Logs By Weight

Pete Van Sickle, Idaho Department of Lands,

Coeur d'Alene, Idaho. Pete gave an overview of the Idaho Department of

Lands timber program as well as their regional scaling load. They have

been gathering weight to volume ratios for some time and now feel

comfortable selling volume on a weight basis. He presented some of the

results of weight to volume analysis that they pointed to their aim of

increasing the number of weight based sales to 80% of their program,

and increasing the component of bigger wood to be included in their

weight sale offers. He did state that large timber (>24" dbh) will

continue to be physically measured. Click here to view the

presentation.

|

|

|

Buying Logs on Weight

Bill McFarling, Neiman Timber Company,

Spearfish, South Dakota. Bill provided a view at their three sawmill

locations and presented comprehensively, the methods and

processes that Neiman uses for their log purchase and inventory systems

which are entirely based on weight and weight converted volumes. He

also covered some of the challenges that they have had to find

solutions for, as well as the difficult situation that the beetle

killed ponderosa pine is creating. Click here to view the

presentation.

|

|

|

Global and Regional Forest Products Economic Trends

Delton Alderman, Researcher, USFS Research Station,

Princeton, West Virginia. Delton presented the current economic

climate for forest products globally and provided the, all important to

North American wood manufacturers, situation with housing in North

America and the world. Many questions remain as to how the sluggish

economy in the US, coupled with a huge supply of unsold houses will

affect the industry. He mentioned that one bright spot was demand from

Asia, which is increasing in China, and at least in the short-term will

likely increase in Japan. Click here to view the

presentation. |

|

|

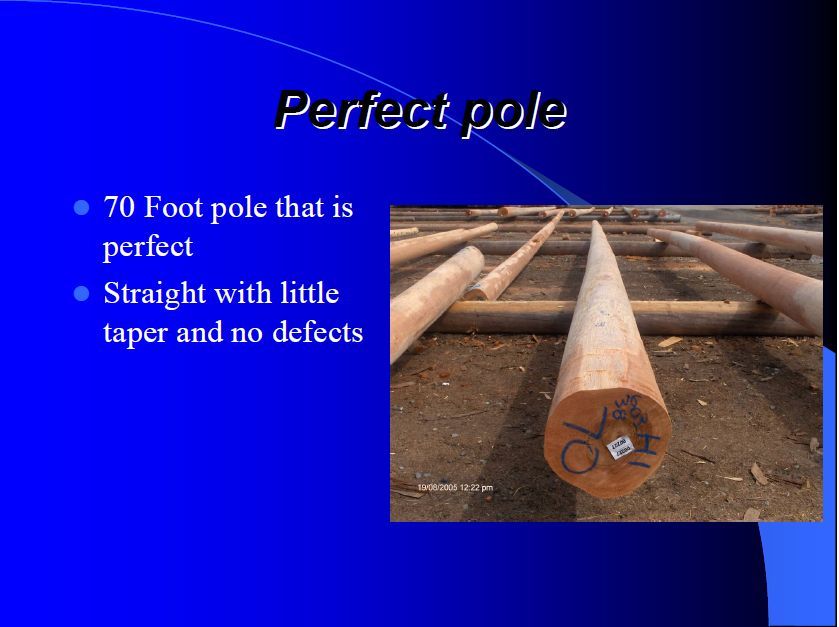

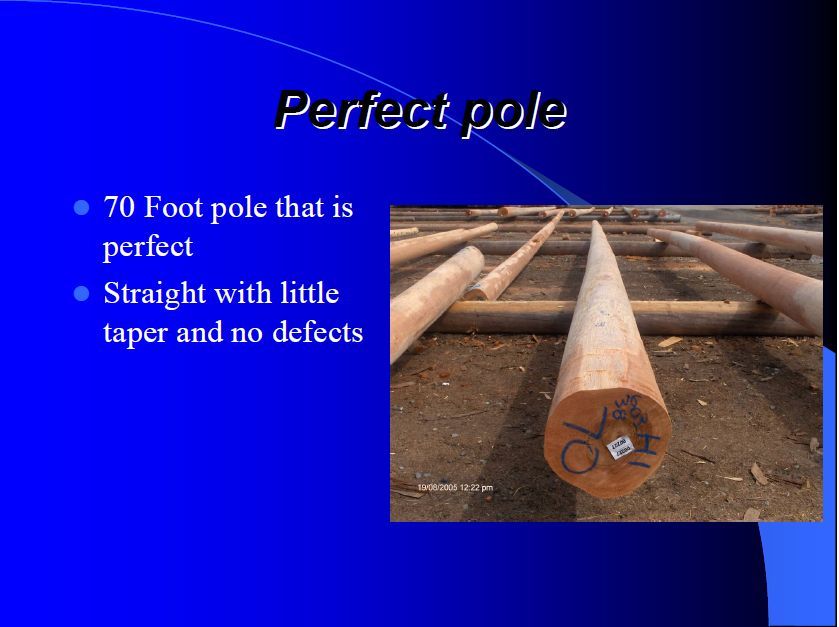

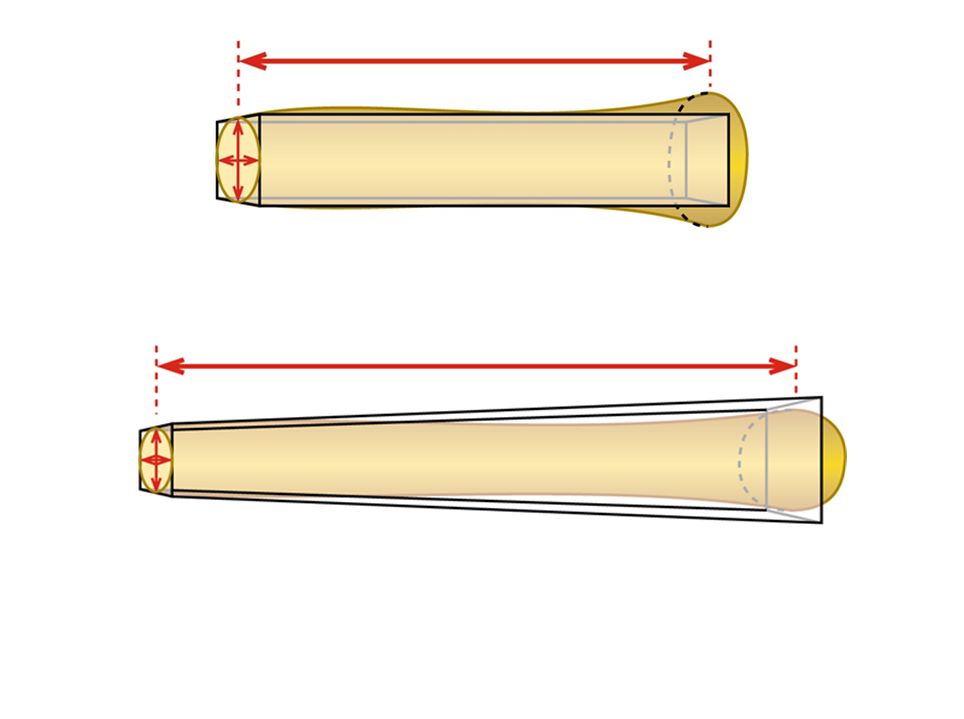

Measurement and Quality Guidelines for Pole Logs

Tom McKenzie, Bell Pole,

Conway, Washington. Tom covered the technical requirements of logs used

to make poles and provided easy to follow examples of defects that are

allowed and those that are not allowed. In addition he proved data on

converting between BC Firmwood scaled logs in m3 vs. Scribner long log

in both standard (1 in 10) and actual taper. Click here to view the

presentation.

|

|

|

The Ultimate Timber Cruise Prescription

Jon Aschenbach, Resource Supply LLC,

Beaverton Oregon. Jon presented a cruising process and procedures that

works well when the stakes are high, e.g., high volume and high valued

stands. He outlined some of the procedural differences, such as using

GPS and other technology to improve accuracy and using good logic in

grid layout, and also advocated what might be interpreted as "old

school" approaches toward minimizing the risk of cruising high valued

stands. Click here to view the

presentation.

|

|

|

Simple Sample Log Scaling: Results of a Study Done on Vancouver Island

Peter

Dyson, Researcher, FPInnovations-Forest Operations, Vancouver, British Columba. Peter gave the

background and results of a study that he worked on in the

Vancouver Island region of British Columbia. In many parts of BC, log

transport is done via water transport, with temporary landings used to

handle, scale and place logs into rafts. As a result of the remote and

temporary location, it is often not feasible to install certified

weight scales. The aim of the

study was to assess the accuracy of sample scaling without the

benefit of log weights to extrapolate load volume to the non-sampled

population, but rather use truck load average to extrapolate. The

results were very interesting. Click here to view the

presentation.

|

|

|

Log Freshness: an Overview of Log Shelf-life Related Quality Issues, their Timing and Prevention

Don Gsell, Weyerhaeuser,

Vancouver, Washington.

Don provided a background on the pathogens and wood properties

issues that affect log grade, and thus sales realization, in the

Pacific Northwest region. He provided some good practices to minimize

preventable degrade as well as shared information on just how much

value can be lost when one does not follow best practices. Click here to view the

presentation. |

|

|

Voice Recognition: Application for Hands-free Log Scaling, Chain Talley and End Talley

Barry Hodgkin, President, Simply Computing International,

Maineville, Ohio.

Barry demonstrated the use of voice data collection for log

scaling. The system uses voice command technology to record log scaling

information and generates scale data and reports in real-time via

software/hardware systems that they put together for their clients.

Advantages include: fewer errors (no more key-punching), the use of

both hands, the scaler can keep his eyes on the logs rather than

needing to view a hand-held screen, and for those working in very cold

conditions - the ability to cover hands in heavy gloves or mittens. The

system also records data quickly and works even where there is

substantial background noise. This system is also used for lumber

grading and tallying, and a timber cruising application is currently

under development. Click here to learn more about this system and the products and services offered. |

|

|

Eastern

Perspectives - the US Northeast Timber Trade: Rules, Misrules,

Conversions, and the 12,000 mile Journey from New England to the Far

East

Hal Wilkins, Van Mohl & Ohnemus GmbH,

Westminster Station, Vermont. Hal presented his experiences and view on

the Northeastern US log market in terms of trade flows. He mentioned

that the region has been a significant log exporting region for some

time now. Despite years of experience, converting between units of

measure has been an ongoing frustration for Hal and his colleagues in

the log trade business. Hal presented the traditional units of measure

of the Northeast and some of the obstacles that he has faced by buying

and selling based on different log scaling methods. Click here to view the

presentation. |

|

|

Measuring Stock-pile Volumes: How to Accurately Assess Volumes of Chips, Residue and Biomass

Jason Martin, Atterbury Consultants,

Beaverton, Oregon. Jason presented a simple, accurate and fast

way of assessing stockpile volumes using MapSmart and a pulse laser

positioning system. The survey and assessment can be done with one

person and conducted on days when aerial assessment would not be

possible. The cost of the equipment is reasonable and the processing

time to input data into MapSmart to calculate volume is minimal (hours)

when compared to other methods. In addition, the system is safe (does

not require the surveyor to climb piles or position themselves in the

path of heavy equipment. Click here to view the presentation. |

|

| April 7, 2011 |

|

New

Method of Cubic Scaling in New Zealand to Replace the JAS Method and

Work on the New Version of New Zealand's Log Scaling Manual

John

Ellis, Group Technical Manager, C3 Ltd.;

and Managing Director of

Scaling

Research International, Mount Maunganui, New Zealand. John has

been working on a new method of scaling logs in New Zealand that

replaces the Japanese Agricultural Standard (JAS) that has been

traditionally used for export logs. While it is often accepted to

purchase logs using the unit of measure from the point of origin of the

logs, the 3-D method, which is traditionally used to ascertain actual

volumes in New Zealand, is not as practical as JAS for use in export as

it requires a large-end diameter (complicated as export logs are

normally scaled on the truck). The 2-D method (derived from the 3-D formula) has shown to assess

volumes accurately and does not have the inherent inaccuracies of the

JAS method, thus reconciling standing inventory does not require

complicated conversion factors. The switch to 2-D will also be

more compatible with other international and automated methods of

assessing diameter and volume. There is still some work to be done on

assessing conversion to Guo Biao (GB) method used in China and

publishing a refereed paper on the method.

John also covered the work that is currently underway to update the New Zealand Procedures for the Measurement of Roundwood,

which was last revised in 1994. The new manual relies heavily on visual

examples to convey procedures rather than text and covers:

measurement procedures and checks, how to measure diameters, length

measurement, methods of estimating wood within log, measurement of log

quality, check scaling, conversion between systems, and formulae and

tables. The section on conversion between systems will have data on

converting between: weight to volume, JAS to cubic, Scribner to cubic,

Huber to cubic, Brereton to cubic and hopefully Guo Biao. John will

keep us abreast of the release and availability of both the paper on

2-D and the revised scaling standards publication.

|

|

|

|

Bark Volume: Assessing Bark as a Fuel for Biomass Energy

Roy Anderson,

Senior Consultant, Beck Group,

Portland Oregon.

Roy gave a brief description of the services that the Beck

Group provides, such as planning, consulting and benchmarking for the

forest products industry and then focused on the current work that he

has done on assessing bark availability for biomass energy. Recently,

with the sudden increase in interest for carbon neutral energy;

biomass, or in this case residue bark from mills, has suddenly

become a valued commodity whereas before it had minimal value. As a

result, there is a demand for data on bark yield in order to conduct

feasibility studies on possible biomass plants. Roy shared some of the

information that they were able to determine and find, as well as their

approach to analysis. Click here to view the

presentation. |

|

|

Terrestrial LIDAR for Forest Measurement and Monitoring

Glen Murphy, Oregon State University,

Corvallis, Oregon.

Glen presented an inventory system that he has been testing,

which is based on terrestrial light detecting and ranging (LIDAR) which

can take accurate measurements. The scanner is mounted on a tripod

and scans 360 degrees (hemispherically), measures millions of points

per second and can scan out in a 30 meter radius. The result is

an accurate set of measurements; not only for establishing size

and volume, but also other grade related criteria, such us crook and

sweep, taper, knot size and number. Click here to view the

presentation. |

|

|

Aerial LIDAR for Forest Inventory

Steve Reutebuch,

USDA Forest Service, PNW Research Station, Cooperative for

Forest-Systems Engineering, University of Washington, Seattle,

Washington. Steve introduced the various types of LIDAR

(terrestrial, satellite, aerial), but focused on aerial LIDAR, with

it's application for measuring forest canopy as the main focus. He gave

an example of satellite being used at a high level, with sub-sampling

done via aerial LIDAR and ground plots to fill in the blanks. LIDAR can

make fairly accurate height measurements, however, it has limitations

in accuracy and because it cannot determine species, among other

things. Click here to view the

presentation. |

|

|

Sampling- the Black Hole in Fibre Measurement and Quality Management Processes

Murray Hall, Murray Hall Consulting Ltd.,

Duncan, British Columbia. Murray gave a presentation based on his

experience in reviewing procedures for sampling wood fibre to

determine bone-dry weight. In the scope of the entire assessment of raw

materials delivered, this aspect has far more potential than any other

for error and bias. Murray outlined what best practices are, based on

his experience and research, and gave some examples of what would

appear to be small errors that lead to huge mis-payments. Click here to view the

presentation. |

|

|

Status of the National Biomass Estimator Library

Troy D. Heithecker, USFS Forest Management Service Center,

Fort Collins, CO. Troy covered the past present and future work

that is being done in developing tools for assessing biomass, which

includes methodology (biomass equations, weight volume ratios, dry

weight equivalents, etc.), and software tools (which are all available

absolutely free). To view the

presentation Click here, and here to go to the Biomass Estimator Library. |

|

|

Setting the Confidence Interval around the Total Inventory Estimate for a Stand-based Inventory

Steve Fairweather, Mason, Bruce & Girard,

Portland, Oregon. Steve presented the use of simulation to determine a

confidence interval on stands that have had inventory assessed via

different methods, which precludes the

use of traditional formulas. In addition, one can use

simulation to answer many questions about inventory procedures and

make-up. Click here to view the

presentation. |

|

|

Log Yard Inventory Measurements: 2011 Update

John Calkins, Simpson Lumber Company,

Shelton, Washington. John gave an update on what he has learned while

working on improving the physical log yard inventory methods and

outlined the technology that he has utilized. The TruPulse 360 forms

the backbone of John's system, but additionally, John has been working

with others in developing systems and software to make log yard

inventory, simple, fast, accurate and repeatable. Click here to

view the presentation. |

|

|

Lodgepole Pine Epidemic: Utilization and Scaling

Ernie Bauer, Executive Director, Idaho Board of Scaling Practices, Coeur d'Alene, Idaho. Ernie

provided background on the mountain pine beetle epidemic and the

challenges faced in determining how best to utilize dead lodgepole pine

(LPP), given the time since the tree was girdled by the beetle.

Additionally, Ernie covered the various approaches used for scaling

LPP, including west and east-side Scribner, BC Firmwood, and USFS

Cubic. Click here to view the

presentation. |

|

|

Update on Logmeter, Drive-through Log Scanning

Mario Angel, WoodTech

- North America, Portland, Oregon. Mario provided background on the

WoodTech company, which is based in Chile, as well as installations in

the US and worldwide. He showed the comparative advantages of

their scanners, which measure load volumes in real time, when a truck

drives through their scanning arch. The scanners can

differentiate logs and chips from the truck and trailer and even

measure attributes such as log diameter length and imperfections such

as crookedness. They are currently working on using cameras on the ends

of the loads, which will increase scanner sensitivity further. Click here to view the presentation. View a

short video on the

Logmeter 4000. |

|

|

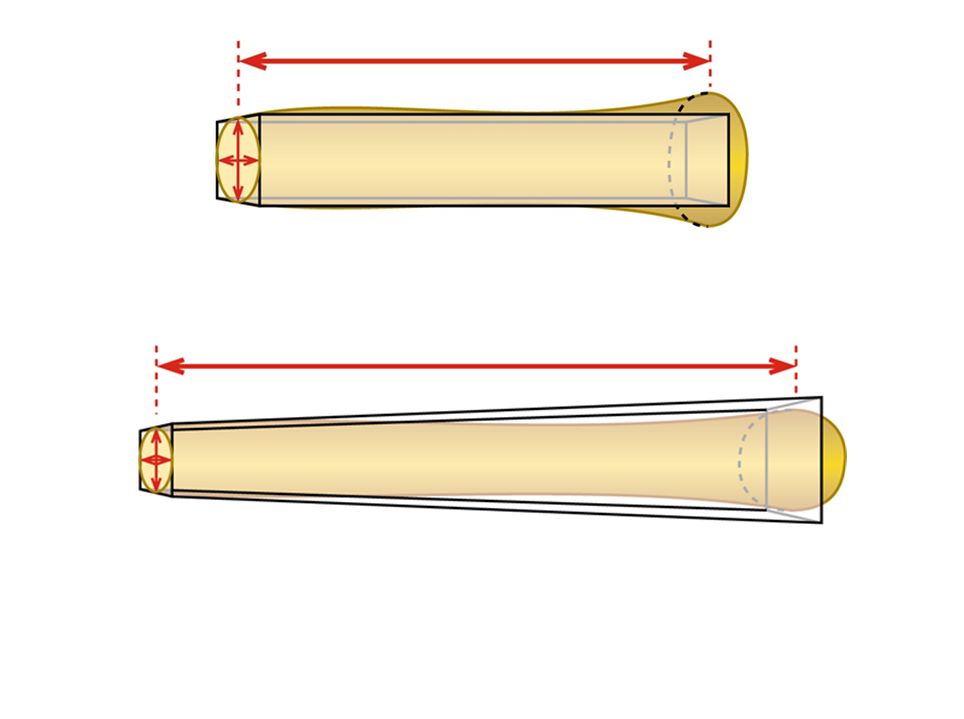

Eastern Washington Standard Taper Issues

Russ Carrier, Boise Cascade, Kettle Falls, Washington.

Russ discussed the situation in Northeast Washington whereby they are

part of USFS Region 6 and thus share the Region 6 standard taper rules

for butt-cut logs, however, their "sourcing area" is shared by mills

from Idaho (Region 1), with very different standard taper rules, thus

generally lower volumes. Russ went on to cover the various different

scenarios of point of origin vs. point of scaling regulations as well

as the often conflicting agency regulations in this area of region

6. Click here to view the

presentation. |

|

| April 8, 2011 |

On

April 9,

we had a field trip to the Simpson mill in Tacoma. Most took a

tour of the mill and participated in a comparison scale on seven group

of logs. The logs included mix of typical Douglas fir and

western

hemlock logs that are used at this mill, however, there were a few

other species as well. The volumes for the loads, using various

scaling methods (average of group), were as follows:

| |

Log dimensions NWLRAG long log* |

Log

dimensions BC |

Scribner board foot

(revised) |

NWLRAG (bureau) cubic foot |

USFS cubic foot |

BC cubic metre |

JAS |

| Load |

Ln' |

d1" |

d2" |

Ln

m |

d1

rads |

d2 rads |

long log gross bf |

long

log net bf |

short

log gross bf |

short

log net bf |

gross ft3 |

firm

ft3 |

net ft3 |

gross ft3 |

net ft3 |

firm m3 |

firm m3 |

| 1 |

31.7 |

8.3 |

11.9 |

10.0 |

11.5 |

15.9 |

3,840 |

3,237 |

5,340 |

4,760 |

1,000 |

985 |

893 |

970 |

892 |

28.75 |

|

| 2 |

40.0 |

11.2 |

14.4 |

12.5 |

15.0 |

19.2 |

4,070 |

4,060 |

5,090 |

5,060 |

908 |

908 |

905 |

873 |

869 |

25.99 |

|

| 3 |

38.9 |

9.8 |

13.6 |

12.2 |

13.2 |

17.8 |

3,613 |

3,477 |

4,680 |

4,390 |

894 |

894 |

862 |

839 |

789 |

25.10 |

|

| 4 |

20.8 |

12.1 |

14.6 |

6.7 |

16.2 |

19.5 |

1,483 |

1,380 |

1,750 |

1,660 |

311 |

311 |

287 |

274 |

260 |

9.03 |

8.67 |

| 5 |

39.4 |

10.5 |

14.3 |

12.4 |

14.1 |

19.0 |

3,483 |

2,637 |

4,510 |

3,370 |

850 |

850 |

604 |

820 |

601 |

24.30 |

24.42 |

| 6 |

35.7 |

9.2 |

12.5 |

11.2 |

12.4 |

16.4 |

3,723 |

3,620 |

4,650 |

4,490 |

925 |

925 |

900 |

883 |

858 |

25.71 |

27.34 |

| 7 |

39.7 |

14.0 |

18.7 |

12.4 |

18.7 |

24.7 |

883 |

717 |

1,150 |

1,000 |

195 |

195 |

164 |

202 |

135 |

5.62 |

5.97 |

| Total |

35.1 |

9.8 |

13.3 |

11.0 |

13.3 |

17.6 |

21,097 |

19,127 |

27,170 |

24,730 |

5,083 |

5,068 |

4,615 |

4,861 |

4,403 |

144.51 |

|

Note:

*Average log diameters for short log Scribner and USFS cubic will be

theoritcally 0.5" larger as a result of truncating each

diameter for long log Scribner.

The following is a brief summary of the some of the key findings when analyzing the log data gathered:

1. For all practical purposes, the NWLRAG cubic scale provided exactly

the same volume as B.C. Firmwood when divided by the 35.315 constant

for ft3 to m3.

2. USFS Cubic gross volume

was generally 95% of BC and NWLRAG cubic, with half the difference from

diameter rounding rules and the other half from unmeasured trim

allowance. The net volume ratio was 1 m3 BC = 0.863 m3 of USFS cubic

(using the 35.315 constant) for this group of logs.

3. Japanese Agricultural Standard scale (JAS) was about 2.7% higher than BC or NWLRAG for the 66 m3 that was compared.

4. One can closely approximate diameters measured in BC rads to inches

in diameters measured by the Sribner methods by dividing

the rads by 1.33 for long log Scribner and 1.28 for short log Scribner.

5. BC m3 to MBF: long log gross = 6.85, net = 7.56; short log gross = 5.32, net = 5.84

6 Long log (west-side) to short log (east-side) Scribner = .777 gross, .773 net.

Thanks to all who participated in scaling the logs. This is very useful information.

After the field trip, the meeting was adjourned at about 2:30 PM.

|

|